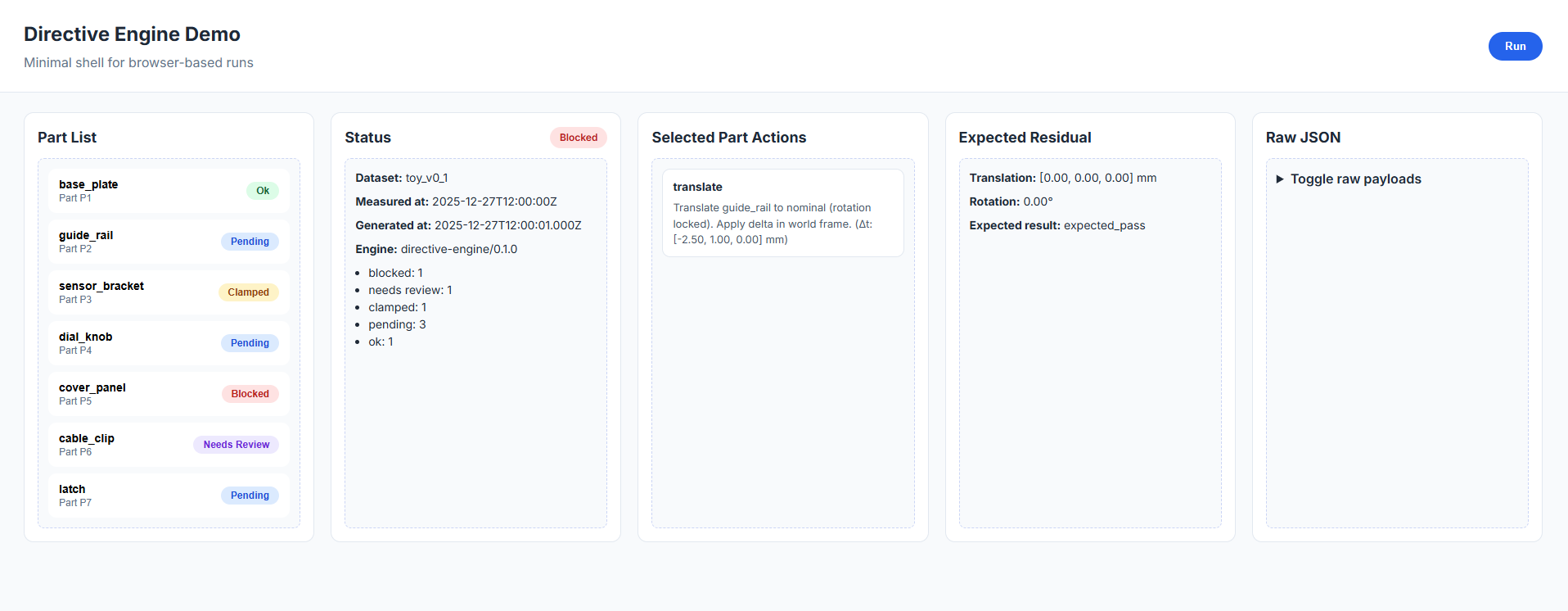

Directive Engine

Convert nominal ↔ as-built deltas into installer-ready directive cards (move/rotate/index), with 3D visualization and verification loops.

Problem

When something is off in the field, the hardest part is not detecting it — it’s expressing the correction in a field-executable format that’s:

Inputs (Signal)

Data format: JSON with paired nominal/as-built coordinates, part IDs, and optional constraint metadata.

Calibration

The engine aligns nominal and as-built coordinate systems using anchor point pairs. Calibration quality is measured by:

RMS > 5mm, re-check anchor pairing before proceeding. High residuals propagate to all downstream directives.

Constraints / DOF

Each part has defined degrees of freedom that limit valid corrections:

Example: Panel P-0132

Panel can only be adjusted in Z-translation and X-rotation (shimming + tilt).

Action Format (Directive Card)

The engine outputs directive cards — structured correction instructions:

DIRECTIVE: P-0132

PENDING

Action: Translate +12mm Z, Rotate -0.3° about X-axis

Frame: Part-local (or site grid)

Verify: Post-adjustment deviation < 3mm

Verification Loop

After applying directives, the system runs a verification pass:

1.8mm (tolerance: 3mm)

Artifacts

Limits + Next Steps

- Single-part directives (no multi-part dependency chains yet)

- Manual anchor pairing (auto-matching in progress)

- Browser-only (no native mobile app)

Roadmap:

- Step ordering / dependencies (anchors → part → verification)

- Confidence scoring +

NEEDS_REVIEWflags for marginal cases - Tolerance heatmaps / clustering visualization

- Optional: AR overlay as a skin, not the core logic